SS - Product Addons

Select product(s) to see addons appear.

This message only appears in theme editor.Welcome to MQS-Shop, your one-stop online store for metrology products and a UKAS accredited calibration laboratory No. 0373.

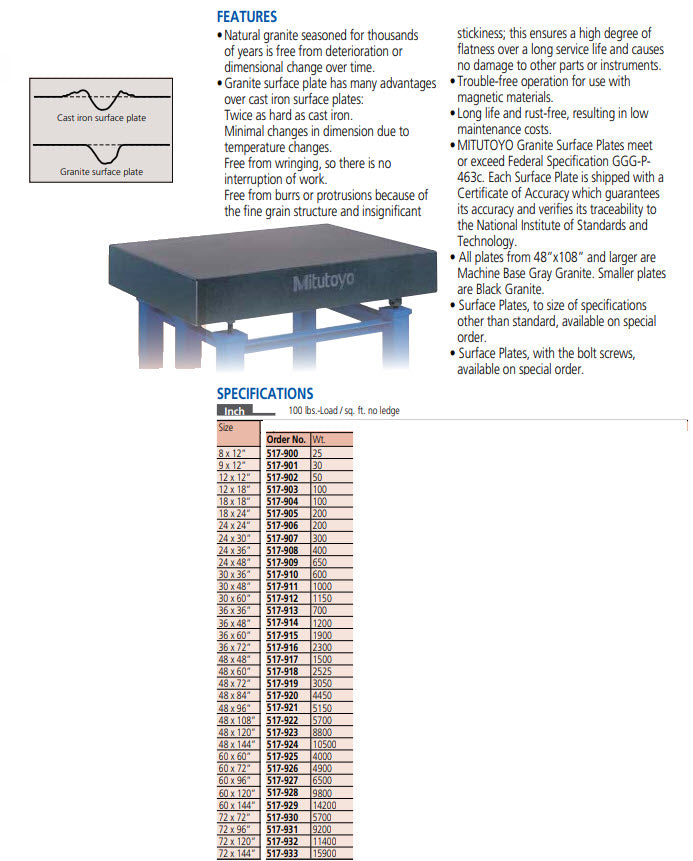

A granite surface plate is an essential investment for laboratories and test facilities. A granite surface plate of 600 x 600 mm can be mounted on a support stand. The stands provide a working height of 34” (0.86m) with five adjustable points for levelling.

For reliable and consistent measurement results, a granite surface plate is crucial. As the surface is a smooth and stable plane, it enables instruments to be carefully manipulated. They are also used in set-up of tooling, production and inspection.

The main advantages of granite surface plates are:

Select product(s) to see addons appear.

This message only appears in theme editor.Free Shipping

Free shipping on orders over £250 (Subject to Terms & Conditions)

Satisfied or refunded

If your not fully satisfied with your purchase return the item with in 14 days for a full refund (Subject to Terms & Conditions)

Customer Support

Contact our customer support team via email or call our hotline number

Secure payments

We offer multiple secure payment options